Are you looking for the best construction cameras to document and protect your jobsite? In your search, you’ve likely run into ratings like IP66 and IK10.

These combinations of letters and numbers might seem cryptic, but they’re actually helpful rating systems that identify a camera’s resilience to several different environmental conditions. Understanding these rating systems is crucial in choosing the right construction camera for your jobsite.

In this blog post, we’ll explore six key rating systems that you need to know when shopping for construction surveillance cameras. We’ll decode all the technical specifications to help you decide on the best cameras for your construction projects.

Camera & Accessories Standards

IP Ratings

Ingress Protection (IP) ratings are sanctioned by the International Electrotechnical Commission (IEC). IP ratings can help you to understand how well your equipment can resist dust and liquids. These ratings are made up of the letters IP followed by two numbers (e.g., IP65, IP68, or IP54).

So, how do you decipher these two-number codes?

- The first number rates the protection against solid objects, ranging from 0 (no protection) to 6 (dust-proof).

- The second number grades how well the enclosure safeguards against liquids, ranging from 0 (no protection) to 9 (withstanding high-pressure hot water from various angles).

IK Ratings

In your search, you’ve also likely seen camera ratings like IK06 and IK09. These are the IK impact resistance ratings.

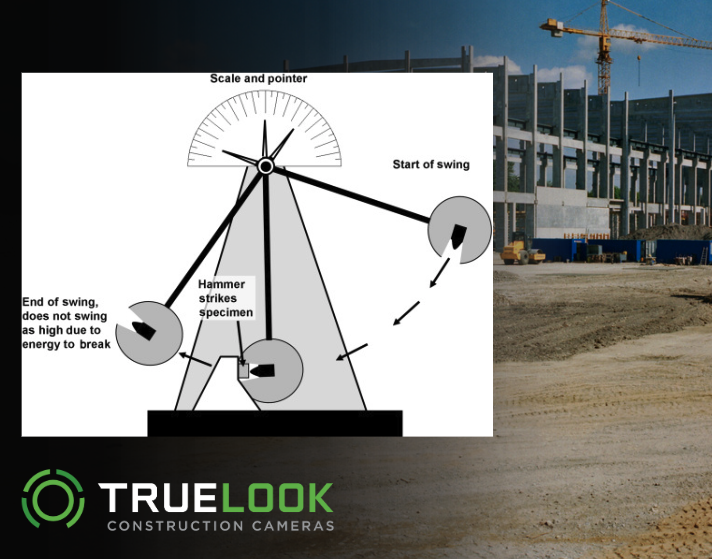

This rating measures how well a camera can withstand impacts. It helps to determine a piece of equipment’s resistance to vandalism, accidental falls, or objects falling onto it. The rating is denoted as “IK” followed by a number ranging from 00 to 10.

The IK rating is assigned through a test involving a hammer attached to a pendulum. The test evaluates the impact energy by considering two key factors:

- The distance between the hammer and the product.

- The weight of the hammer.

The product is subjected to three identical impacts, and the highest impact level at which it still functions determines its assigned rating.

For example, IK06 is appropriate for construction cameras installed in less hazardous areas where the risk of impact is relatively low, such as on the roof of a neighboring building.

On the other hand, IK10 is crucial for construction cameras positioned in high-traffic zones or areas with a higher risk of impact, such as those mounted on electric poles, building exteriors, or at the base of demolition operations. These cameras require maximum protection to withstand potential collisions, debris, or impacts.

NEMA Ratings

A NEMA (National Electrical Manufacturers Association) rating indicates an electrical enclosure’s level of protection against environmental factors like dust, moisture, and corrosion. In the construction camera industry, many cameras require an electrical enclosure (often called a control or battery box) to store modems, batteries, and other components.

While NEMA may sound similar to an IP rating, they differ in that IP ratings are typically for the camera enclosures themselves, while a NEMA rating is for the camera’s control box. NEMA ratings are also specific to North America, but IP ratings are internationally recognized.

NEMA ratings for outdoor equipment include 1, 3, 3R, 4, 4X.

These numbers might look confusing at first, so here are a couple of general rules to help you decipher them:

- The higher the number, the greater the level of protection.

- The “R” stands for “rain,” indicating that the enclosure is designed to protect against the ingress of rain, sleet, and snow.

- The “X” stands for “protection against corrosion” indicating that the enclosure has additional protection features beyond the NEMA number.

Let’s break down a few key NEMA ratings you might encounter:

- NEMA 1: Designed for indoor use, protecting equipment against solid foreign objects and falling dirt.

- NEMA 3: Suitable for indoor or outdoor use, protecting against access to hazardous parts, falling dirt, windblown dust, and water ingress.

- NEMA 4: Ideal for indoor or outdoor applications, protecting against solid foreign objects, water, and even hose-directed water.

For outdoor jobsite cameras, a NEMA 4X rating is best to fully protect against weather, water, and solid objects. Plus, corrosion-resistant materials will ensure the camera’s longevity.

UL Ratings

UL, or Underwriters Laboratories, is a highly trusted organization that sets the standard for quality products across many industries. UL’s role is to assess products, test components, evaluate performance, and ensure the sustainability of various technologies.

Unlike the rating systems above, UL ratings don’t indicate a certain level of quality. Rather, they serve as category labels.

For example:

- UL 2218 – Certifies roofing materials for their resistance to hail damage.

- UL 723 – Measures flame spread and smoke development of building materials for fire safety.

- UL 2079 – Ensures fire-rated joint systems maintain integrity during a fire.

In our field, UL ratings are relevant to cameras with control boxes. The UL rating for control boxes is UL 508, which means that they are built for UV resistance and flammability.

Security Ratings

While the ratings above determine a camera’s resistance to environmental conditions, the following security ratings demonstrate a monitoring company’s commitment to security and reliability. These ratings are important to keep in mind for jobsite cameras that utilize live professional monitoring for after-hours protection.

5 Diamond Certified

A 5 Diamond Certification is awarded to companies that meet stringent requirements set by The Monitoring Association (TMA). To achieve 5 Diamond Certification, companies have to demonstrate the following:

- Commitment to rigorous inspections and quality standards by nationally recognized testing laboratories like FM Approvals, Intertek/ETL, and UL.

- Dedication to providing top-tier customer service.

- Investment in continuous education and training for all monitoring operators, with certification completed through the TMA online training series.

- Active participation in TMA activities and membership to enhance industry standards.

- A commitment to reducing false dispatches.

As a consumer, choosing a Five Diamond Certified monitoring company ensures that you receive the highest level of service and protection for your construction site. These companies prioritize professionalism, expertise, and adherence to industry standards.

UL Listed

UL Listed is a type of UL Certification. It indicates that a monitoring facility adheres to UL’s rigorous standards for quality and safety. Unlike a general UL categorization, which applies to a wide range of products, being UL Listed specifically refers to monitoring facilities.

To become UL Listed, a company must:

- Meet the UL’s established standards for alarm systems and monitoring centers.

- Undergo an on-site inspection to ensure compliance with UL 827 standards, followed by annual audits.

- Receive a Certificate of Compliance upon passing the initial exam.

- Be listed on the UL’s online directory for consumers to find reputable providers.

- Keep up with the latest UL certification requirements.

This certification ensures that a monitoring facility has a track record of reliability and experience in alarm response and monitoring.

The Bottom Line on Construction Camera Ratings

In the construction industry, choosing the right surveillance cameras is crucial. From IP ratings ensuring protection against dust and liquids to IK ratings gauging impact resistance, you can use these systems as a guide when searching for cameras.

Learn how TrueLook can elevate your jobsite today!

Our experts are standing by to provide you with a customized recommendation based on your jobsite.